Power Hacksaws are usually of simple construction whose cutting action is brought about the reciprocating motion of the saw blade. It consists essentially of a drive unit, crank mechanism, slide, feed weight, a clamping unit and a frame which carries all the above units.

An electric motor is the source of power, mounted at the bottom to one side of the frame, The crank is a disk which carries a slot or a set of holes onto which the link is attached. The link actuates the slide onto which the saw blade is clamped. The slide has an inverted U shape on top of which there is a feed weight. The feed weight is fixed in position by a link attached to the upper part of the machine frame. By moving the feed weight along the link, the weight acting on the saw blade can be varied. The greater the weight acting at the saw blade, the higher the feed rate, That is, the lesser time it takes to cut the work-piece.

The Crank is driven by the electric motor through vee-belts and a pulley only, or in conjunction with a pinion and wheel drive. The work-piece is clamped in a machine vice with opposed - travel jaws. The stroke of the slide is adjusted by adjusting the crank pin on the crank slot. The slot gives a step less stroke adjustment.

In some designs, two, three, or four holes are used for step - wise stroke adjustments. The power hacksaw is usually of a cast construction with the major component made from castings, However, Power hacksaws of welded construction exists for one - off or low piece production. The capacity of power hacksaws are given by the maximum size of work that can be sawn. Usual capacities range from 75 x 75mm square or round stock for a large machine.

Most power hacksaws have facility for the cutting off of repetitive parts which consists of a long - rod, with a stopper at one end. The rod can be adjusted such that the distance between the stopper and the fixed saw blade can be varied to suit the length to be cut. Most power hacksaws have circulating coolant system.

It should be noted that when sawing generally, It is faster to cut through a smaller thickness than through a larger one.

For Example; It is faster to cut the 25mm thickness on a solid bar of 25 x 50mm, than through the 50mm thickness.

The tooth profiles of power hacksaw, blades are similar to those of hand hacksaw except that the former and bigger and sturdier.

Blade materials are usually carbon tool steels and high speed steels. Carbon steel blades are cheaper but have low life due to frequent breakage and high tooth wear. Due to unavailability of tool materials in Nigeria, Both hand and power hacksaw blades have been made from leaf springs, scrap saw mill blades and mild steel strips ( which were case hardened ).

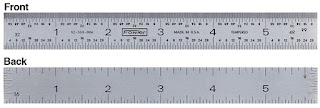

Power saw blades come in different sizes and pitches. Some particular sizes are L x W x T x N = 350 x 25 x 1.25 x 14 teeth and 400 x 32 x 1.60 x 10 teeth, Where L, W and T are the length, width and thickness of the blade in (mm) respectively and n is the number of teeth per 25mm length of blade.